chemical dosing system like polymer urban and industrial wastewater treatment dissolved air flotation system

Product Introduction

- It is a widely-used solid-liquid separation equipment in wastewater treatment industry.

- It can effectively remove the suspensions, oils, and adhesives in the wastewater, one of the key equipment in the early processing.

- It can remove the floated flocs that are difficult to precipitate. With its large capability, high efficiency, less space consumption and wide application.

- It has been widely applied in oil, chemical, printing and dyeing, papermaking, refining, leather, steel, mechanical processing, starch, food and other wastewater treatmentWorking Principle

Packing & Delivery

The normal package is wooden box(Size: L*W*H). If export to european countries, the wooden box will be fumigated. If container is too tigher, we will use pe film for packing or pack it according to customers special request.

Product Introduction

- It is a widely-used solid-liquid separation equipment in wastewater treatment industry.

- It can effectively remove the suspensions, oils, and adhesives in the wastewater, one of the key equipment in the early processing.

- It can remove the floated flocs that are difficult to precipitate. With its large capability, high efficiency, less space consumption and wide application.

- It has been widely applied in oil, chemical, printing and dyeing, papermaking, refining, leather, steel, mechanical processing, starch, food and other wastewater treatment

Working Principle

The dissolving air tank can produce dissolving gas which later be released to the water waiting to be treated through the release device. It will form tiny bubbles of 20-40um and those tiny bubbles will combine with suspended solids in the waste water to make the proportion of these suspended solids smaller than water and gradually float to the surface to form scums. With a scraper system on the surface, these scums will be scraped into the sludge pool while the water will enter the clean pond from the lower part of the overflow trough.

Feature:

1.These tiny bubbles have great air flotation effect.

2.In the operating process, the low consumption of the polymer makes the cost pretty low.

3. It is very easy to control the water quality and water quantity by controlling the operation of the equipment strictly through the control system.

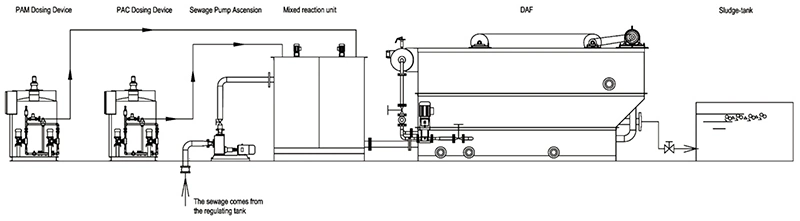

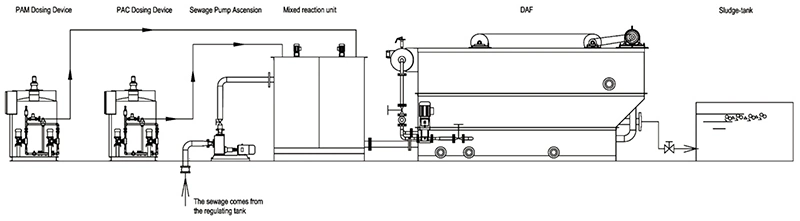

Process flow chart

2.In the operating process, the low consumption of the polymer makes the cost pretty low.

3. It is very easy to control the water quality and water quantity by controlling the operation of the equipment strictly through the control system.

Technical Parameters | |||||||

Model | Capacity (m³/h) | Air dissolving water (%) | Motor power (kw) | Scrape power (kw) | Air compressor power (kw) | Air dissolving tank (mm) | Dimension (L*W*H) |

MPQF-5 | 4-5 | 35 | 3 | 0.37 | 1.5 | 400*1000 | 3300*1800*2200 |

MPQF-10 | 8-10 | 35 | 3 | 0.37 | 1.5 | 500*1512 | 4000*2100*2200 |

MPQF-15 | 10-15 | 35 | 3 | 0.37 | 1.5 | 500*1512 | 4400*2100*2200 |

MPQF-20 | 15-20 | 35 | 7.5 | 0.37 | 1.5 | 500*1512 | 4600*2400*2200 |

MPQF-30 | 20-30 | 35 | 7.5 | 0.37 | 1.5 | 500*1512 | 5200*2600*2400 |

MPQF-40 | 30-40 | 35 | 7.5 | 0.55 | 1.5 | 600*1880 | 6000*2600*2400 |

MPQF-50 | 40-50 | 35 | 7.5 | 0.55 | 1.5 | 600*1880 | 7000*2600*2400 |

MPQF-60 | 50-60 | 35 | 7.5 | 0.55 | 1.5 | 600*1880 | 7600*2800*2400 |

MPQF-70 | 60-70 | 35 | 7.5 | 0.55 | 1.5 | 650*2034 | 8400*2800*2400 |

MPQF-80 | 70-80 | 35 | 7.5 | 0.55 | 1.5 | 650*2034 | 9200*2800*2400 |

MPQF-100 | 90-100 | 35 | 7.5 | 0.55 | 3 | 700*1980 | 10000*2800*2600 |

MPQF-150 | 125-150 | 40 | 22 | 1.1 | 3 | 700*1980 | 13500*2800*2600 |

MPQF-200 | 175-200 | 40 | 22 | 1.1 | 3 | 800*2100 | 15800*2800*2600 |

MPQF-300 | 250-300 | 40 | 37 | 1.1 | 5.5 | 800*2100 | 19200*3400*2800 |

Process flow chart

Company Profile

Packing & Delivery

The normal package is wooden box(Size: L*W*H). If export to european countries, the wooden box will be fumigated. If container is too tigher, we will use pe film for packing or pack it according to customers special request.

Delivery time: 3~45 days after confirming order, the detailed delivery date should be decided by the production season and order quantity.

Why choose us ?

SATISFACTORY SERVICE

- Quick Response Time, 7×24 hours Technical Consultation

- Feel Free to consult, customized solution for your application.

- Engineers are available to service machinery overseas.

- Factory audit is welcomed

- Our extinguished clients include BASF, Tialoc and CNPC.

- Train how to install and operate the machine.

- Complete video operation tutorial

ADVANCED DEWATERING TECHNOLOGY

- R&D Cooperation with Tsinghua University

- Superior Raw Materials

- Laser cutting adopts Trumpf technology and the anti-corrosion materials adopt Starck technology

- Quick Response Time, 7×24 hours Technical Consultation

- Feel Free to consult, customized solution for your application.

- Engineers are available to service machinery overseas.

- Factory audit is welcomed

- Our extinguished clients include BASF, Tialoc and CNPC.

- Train how to install and operate the machine.

- Complete video operation tutorial

ADVANCED DEWATERING TECHNOLOGY

- R&D Cooperation with Tsinghua University

- Superior Raw Materials

- Laser cutting adopts Trumpf technology and the anti-corrosion materials adopt Starck technology