SCREW PRESS DEWATERING MACHINE

Sludge dewatering screw press is a screw press that separates liquids from solids. A screw press can be used in place of a belt press, centrifuge, or filter paper. It is a simple, slow moving device that accomplishes dewatering by continuous gravitational drainage. Screw presses are often used for materials that are difficult to press, for example those that tend to pack together. The screw press squeezes the material against a screen or filter and the liquid is collected through the screen for collection and use.

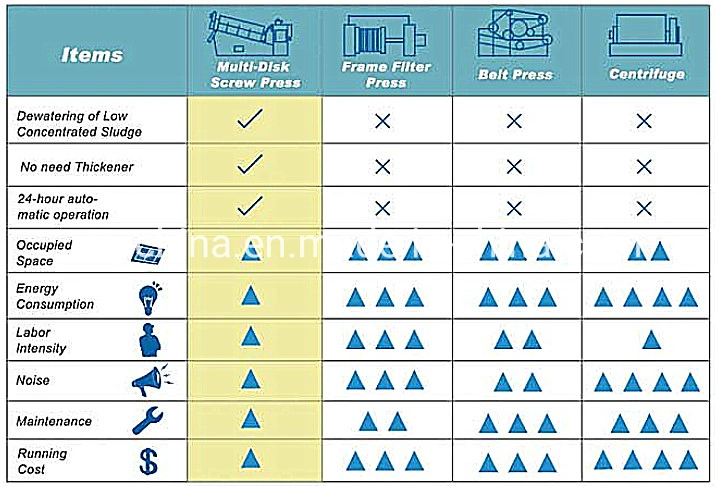

Advantages

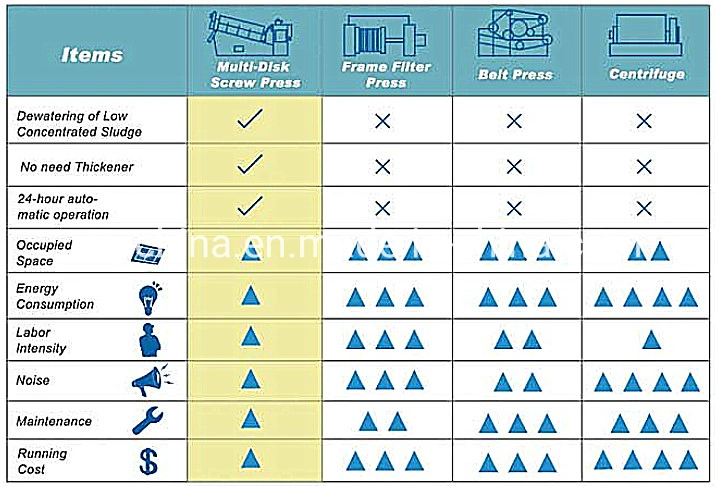

Low operation cost: less than 40% of that of belt filter press, and less than 20% of that of centrifugal dewaterer;

Power saving: less than 5% of that consumed by the centrifugal dewaterer; water saving: less than 0.1% consumed by the belt filter press; and medicine saving: saved by 60%

Small volume: save the investment into dewatering room; non-blocking: the strong opponent against oil and fiber sludge;

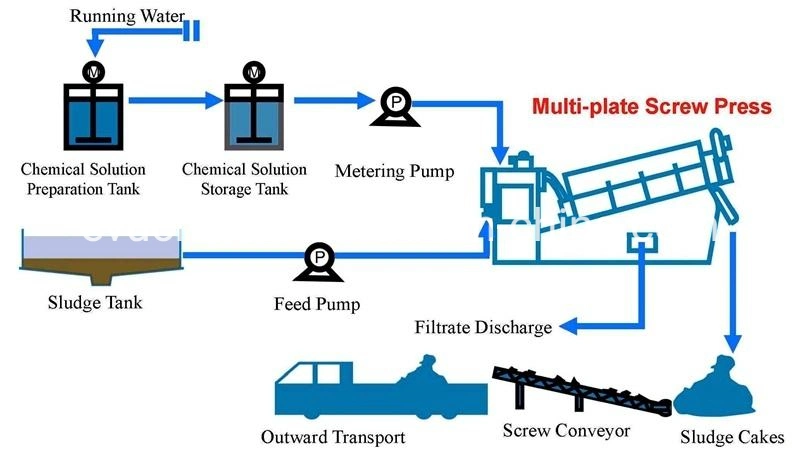

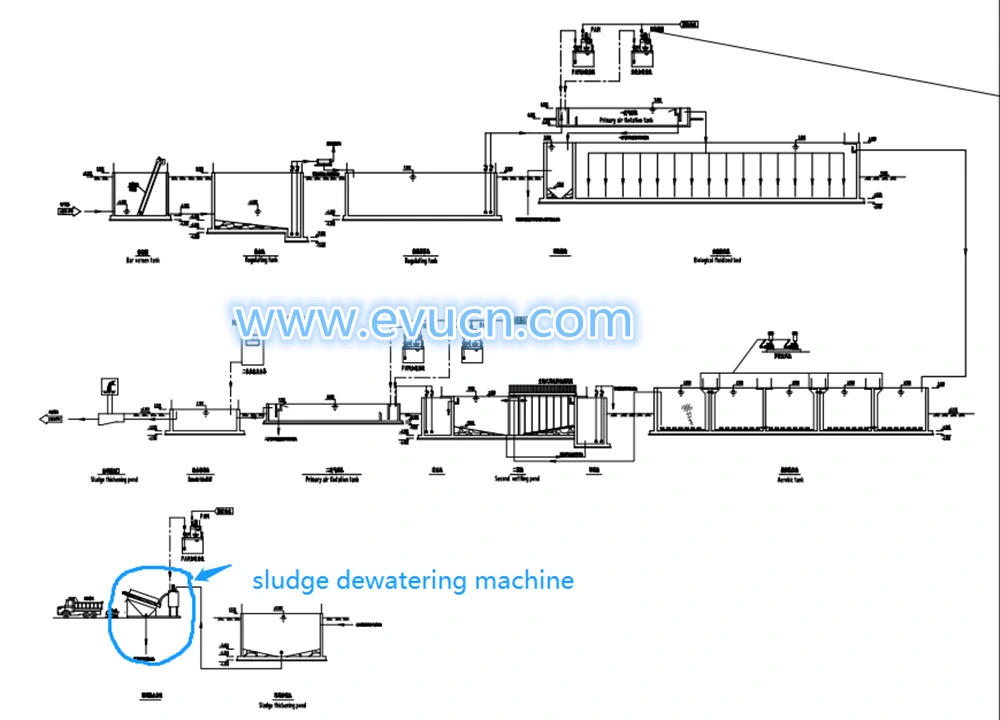

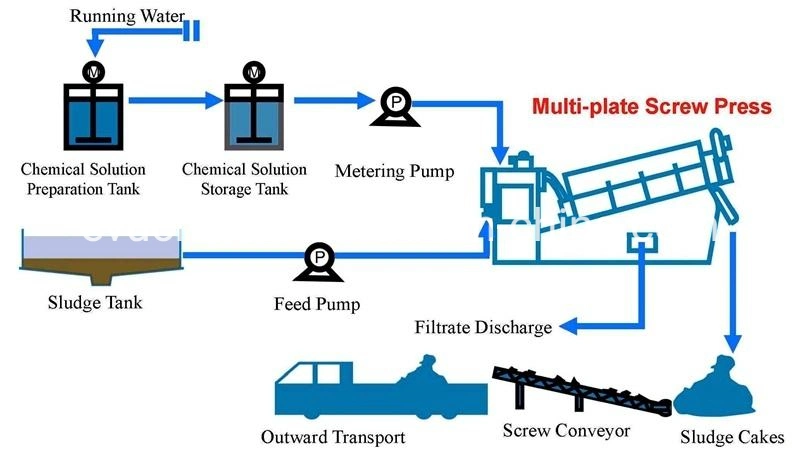

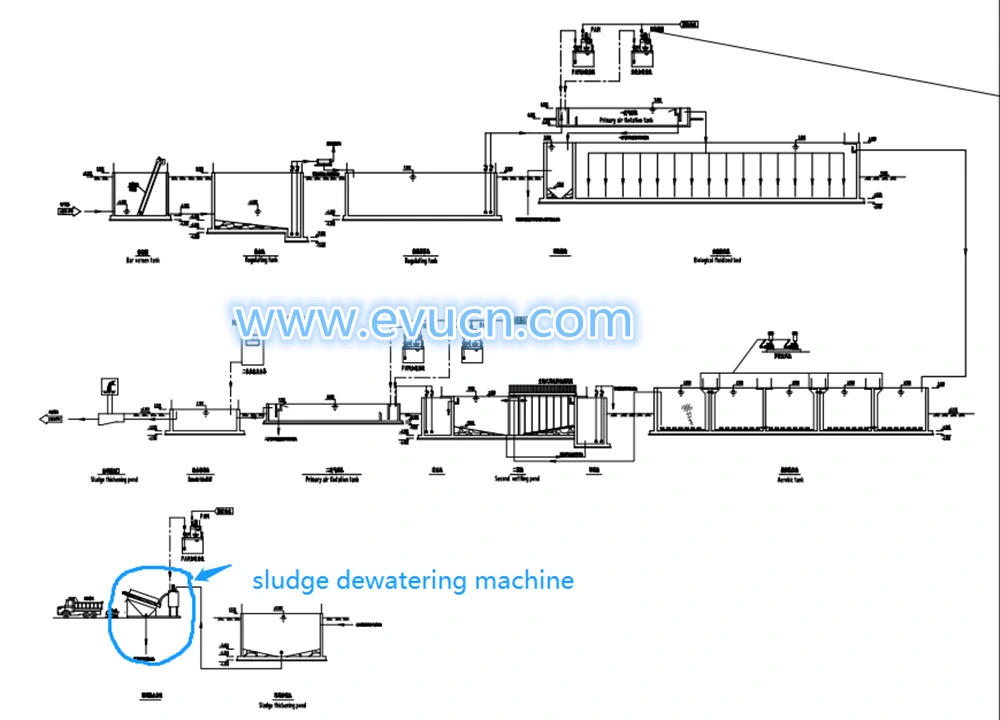

Sludge Treatment Process

Multi-disk screw press, also known as MDS dewatering press, is a kind of cutting edge sludge dewatering equipment with non-clogging design and low energy consumption, especially applicable for oily sludge.

QDEVU Dewatering Machine Parameter

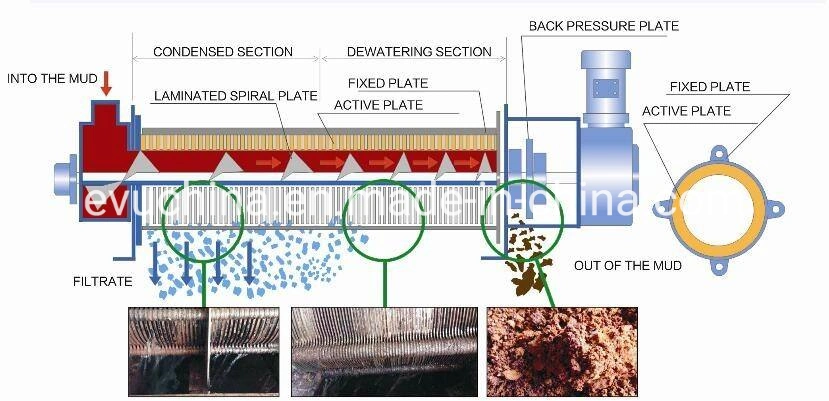

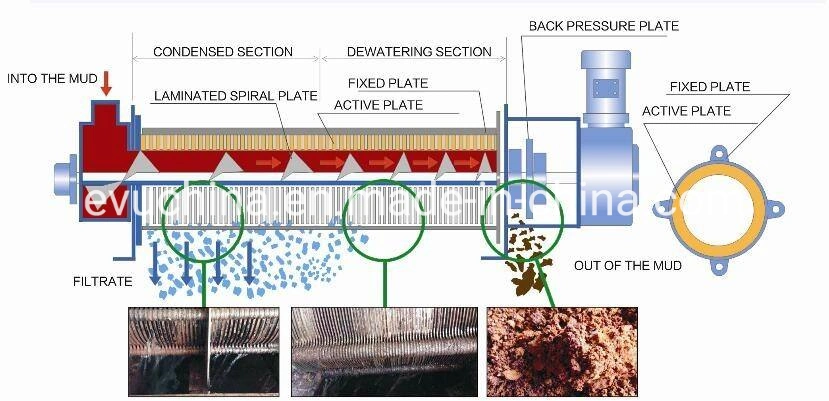

Dewatering Principle

The initial section of dewatering drum is the thickening zone, where the solid-liquid separating process takes place and where the filrate will also be discharged.The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, hence increasing its internal pressure. At the end, the end plate further increases the pressure, so as to discharge dry sludge cake.

Main Features & Comparison

Application

Certificates

Qingdao EVU Environmental & Engineering Equipment Co.,Ltd(EVU) has key technological inputs from it's German partners and over more than 20 years water treatment experience.

Engaged in engineering consulting, design, general contracting and equipment manufacturing of water treatment equipment. Its business spectrum covers both domestic and industrial waste water treatment, pure water treatment, seawater desalination and water recycling.

EVU has very strong commitment to the four cardinal principles of quality standards, system stability, cost control and service-oriented principles as the basis for its survival and development.

Sludge dewatering screw press is a screw press that separates liquids from solids. A screw press can be used in place of a belt press, centrifuge, or filter paper. It is a simple, slow moving device that accomplishes dewatering by continuous gravitational drainage. Screw presses are often used for materials that are difficult to press, for example those that tend to pack together. The screw press squeezes the material against a screen or filter and the liquid is collected through the screen for collection and use.

Advantages

Low operation cost: less than 40% of that of belt filter press, and less than 20% of that of centrifugal dewaterer;

Power saving: less than 5% of that consumed by the centrifugal dewaterer; water saving: less than 0.1% consumed by the belt filter press; and medicine saving: saved by 60%

Small volume: save the investment into dewatering room; non-blocking: the strong opponent against oil and fiber sludge;

Sludge Treatment Process

Multi-disk screw press, also known as MDS dewatering press, is a kind of cutting edge sludge dewatering equipment with non-clogging design and low energy consumption, especially applicable for oily sludge.

QDEVU Dewatering Machine Parameter

| MODEL | DS STANDARD CAPACITY (KG/H) | FLOW LOAD (M3/H) | |||||

| LOW CONCENTRATION | HIGH CONCENTRATION | 2000MG/L | 10000MG/L | 20000MG/L | 30000MG/L | 50000MG/L | |

| QDLX-131 | 4 | 26 | 26 | 0.6 | 0.5 | 0.87 | 0.4 |

| QDLX-132 | 8 | 52 | 52 | 1.2 | 1.0 | 1.73 | 0.8 |

| QDLX-201 | 8 | 52 | 52 | 1.2 | 1.0 | 1.73 | 0.8 |

| QDLX-202 | 16 | 104 | 104 | 2.4 | 2.0 | 3.47 | 1.6 |

| QDLX-301 | 20 | 130 | 130 | 3.0 | 2.5 | 4.33 | 2.0 |

| QDLX-302 | 40 | 260 | 260 | 6.0 | 5.0 | 8.67 | 4.0 |

| QDLX-303 | 60 | 390 | 390 | 9.0 | 7.5 | 13 | 6.0 |

| QDLX-351 | 40 | 260 | 260 | 6.0 | 5.0 | 8.67 | 4.0 |

| QDLX-352 | 80 | 520 | 520 | 12 | 10 | 17.3 | 8.0 |

| QDLX-353 | 120 | 780 | 780 | 18 | 15 | 26 | 12 |

| QDLX-354 | 160 | 1040 | 1040 | 24 | 20 | 34.68 | 16 |

| QDLX-402 | 135 | 884 | 884 | 20 | 17 | 29.5 | 13.6 |

| QDLX-403 | 200 | 1326 | 1326 | 30 | 25.5 | 44.2 | 20.4 |

| QDLX-404 | 266 | 1768 | 1768 | 40 | 34 | 58.9 | 27.2 |

Dewatering Principle

The initial section of dewatering drum is the thickening zone, where the solid-liquid separating process takes place and where the filrate will also be discharged.The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, hence increasing its internal pressure. At the end, the end plate further increases the pressure, so as to discharge dry sludge cake.

Main Features & Comparison

Application

Certificates

Qingdao EVU Environmental & Engineering Equipment Co.,Ltd(EVU) has key technological inputs from it's German partners and over more than 20 years water treatment experience.

Engaged in engineering consulting, design, general contracting and equipment manufacturing of water treatment equipment. Its business spectrum covers both domestic and industrial waste water treatment, pure water treatment, seawater desalination and water recycling.

EVU has very strong commitment to the four cardinal principles of quality standards, system stability, cost control and service-oriented principles as the basis for its survival and development.